Manufacturing Engineering

型材挤压

|

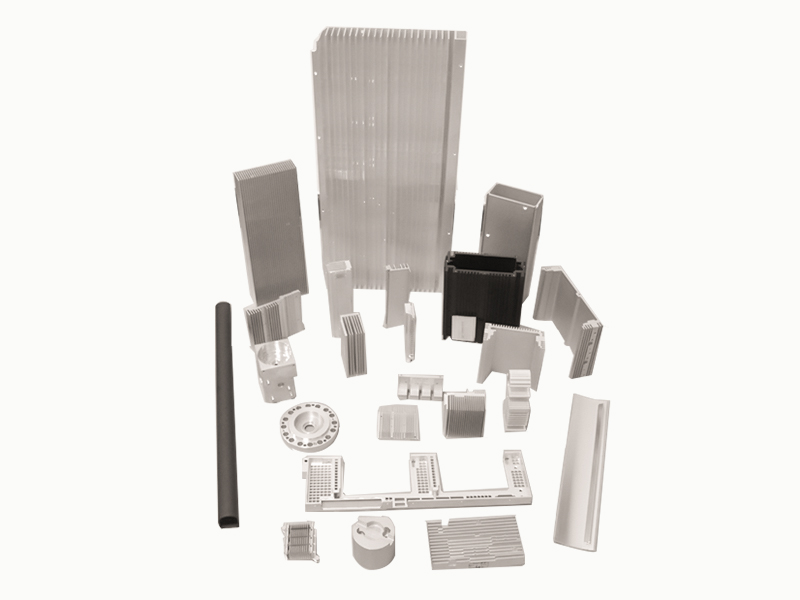

1. Concept: The profile with complex cross section and high precision can be extruded at one time. Aluminum profile extrusion is a kind of plastic processing method which applies external force to the aluminum alloy blank placed in the container (extrusion cylinder) to make it flow out of the specific die hole to obtain the required cross-section shape and size. It can produce high-precision profiles and meet the different needs of customers. |

|

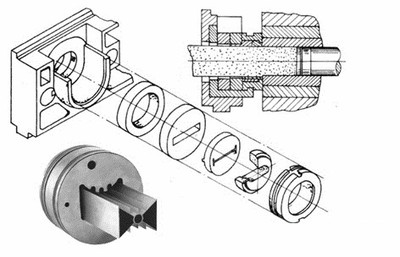

2. Mold design: Through the analysis of the size, weight and strength of the profile section, the size of the die and the tonnage of the equipment are determined. After calculation, the metal flow speed is adjusted reasonably, and the profile die with long service life and working under various harsh conditions is designed to ensure that the profile accuracy meets the production requirements. |

|

3. Extrusion processing: By heating the cylindrical aluminum rod of about 500 ° C into the container, using various types of die high pressure hot processing method, the complex cross-section shape of aluminum can be completed by extrusion at one time. According to the unique program and processing parameters of different kinds of products, it is input into the equipment control system, and combined with simulation calculation, the extrusion conditions of profile are controlled to ensure that the extruded products meet the requirements Various high precision requirements in the field of electrical appliances, machinery industry and automobile industry. |

|

4. Tempering treatment: After the profile extrusion die is quenched by air cooling, the distortion and bending deformation caused by the temperature difference of the profile should be corrected by the traction of traction machine to eliminate the deformation and reduce the residual stress, improve the strength characteristics and maintain its good surface. After correction, it can be cut into various lengths required by customers. After passing the section size inspection, the aluminum profile is annealed at about 200 ° C. after annealing, the aluminum profile is finished. |

Profile cutting

|

1. Cutting: The length required by customers can be achieved by sawing the profiles. In order to meet the production requirements, we have introduced a number of high-precision automatic cutting equipment, such as automatic cutting machine, manual cutting machine, double head angle cutting machine, and groove cutting machine, which can meet the cutting requirements of various high-precision products. |

Stamping

|

1. Stamping: Compared with castings and forgings, stamping parts are thin, uniform, light and strong. In order to improve the rigidity of the workpiece with stiffeners, stamping ribs, undulating or flanging, which are difficult to manufacture by other methods, can be produced by stamping. Due to the use of precision die, the precision of workpiece can reach micron level, and the repetition precision is high and the specification is consistent. It can make blanking, punching, forming, drawing, trimming, fine blanking, shaping, riveting and extruding parts. |

|

(1) Press of various tonnage |

(2) Hydraulic press |

Precision CNC machining

|

1. Precision CNC machining: The company adheres to the production concept of precision manufacturing, high quality and standard, and constantly introduces high automation equipment. |

||

(1) Large CNC machining center |

(2) Medium sized CNC machining center |

(3) CNC lathe |

Duty Machinery & Electron

Duty Machinery & Electron